Four or five ply belting?

Understanding conveyor belt markings.

When quoting to supply a new belt, customers will often specify how many plies the want in the belt as they believe this is a guarantee of durability, and whilst this can be a guide it isn’t critical.

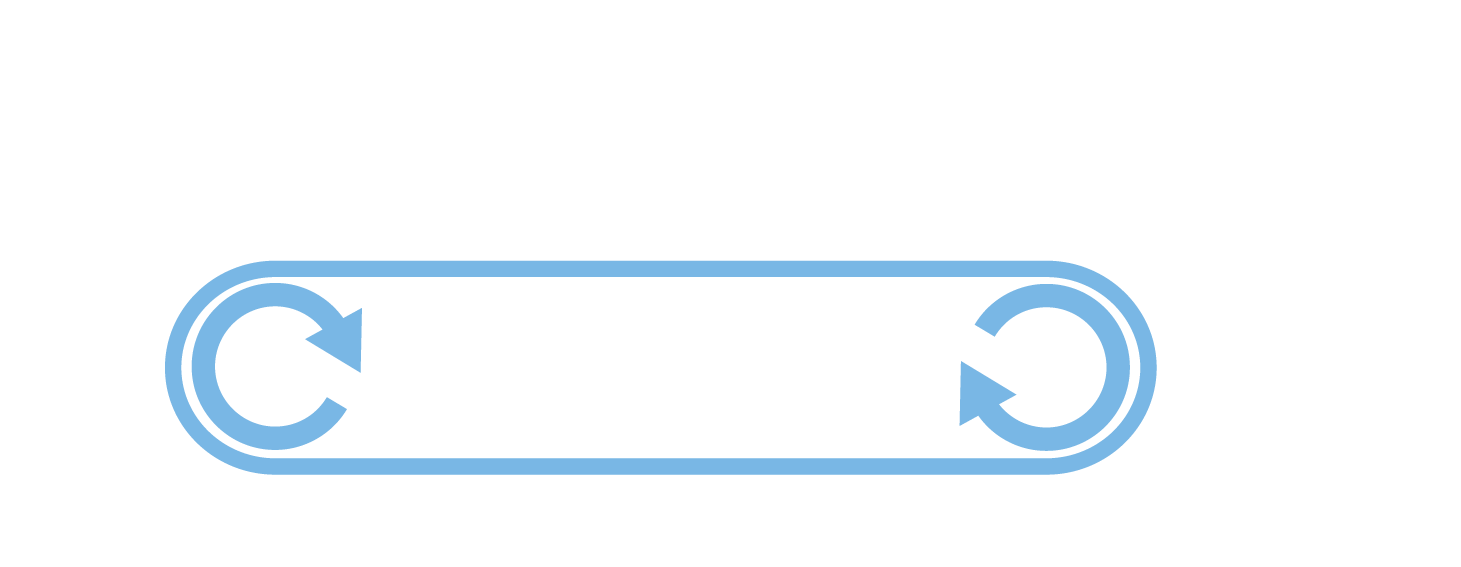

The example shown in the image is 400/3 3.5/1.5. This belt is 400 kN/m in strength, 3-ply, with 3.5mm top cover and 1.5mm bottom cover taking the total to 8mm

When compared to the specialist Dunlop UsFlex belt of 400/1 4/2.5 9mm thick you can see that the single ply belt is the same strength as the three ply but the thicker cover means longer wear life and better impact resistance.

This lack of understanding is often used to secure a contract by offering substandard belting; a customer requests a 4 ply belt and is given a 10mm 500/4 instead of the 12mm 630/4 they require.

In short, when ordering belting, focus on thickness as well as number of plies… or simply contact us.